ENGINEERING

AND CONSTRUCTIONS

ADI S.A. CONTRIBUTES IN GREAT VENTURES

Among our clients today we have the most important organizations regarding petroleum, gas, petrochemical and industrial constructions.

We

treat each order of purchase as a complete venture and

we control assigning

it to a

person in charge in the pursuit of terms and specifications

agreed step by step according to the necessities of the client.

For this we offer the combination of Engineering, assembly and pre-commissioning until we can guarantee the operation of the plant in the areas that we intervene.

Among

our Clients are important Companies as:

YPF, TGS, MONSANTO, ASTRA, TGN, PETROQIMICA WHOSE, SHELL,

ISAURA, PETROKEN, TELECOM, TELEFONICA, etc..

Be

this in a direct way or through

constructors such as:

TO EVANGELISTA, TAURUS, TECHINT, SADE

All the works are made preparing a plan of tasks and another one of inspections and / or other tests requirements, according to techniques in quality control and specifications by the client, to be able to guarantee the requirements of the industry in their different degrees or levels.

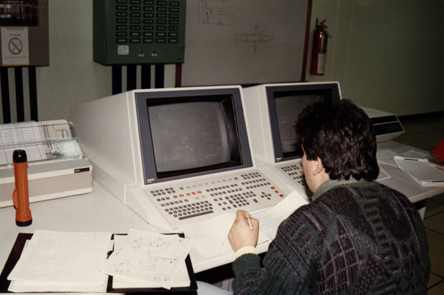

Engineering is made following the same traditional

structure

that our provisional ones applied when they worked in first-class

companies such as TECHINT, AESA, SHELL, MC KEE

(CPC), TECNOR, etc. but with the addition of modern tools of

the present software and with

“aggiornamiento” of the new systems of distributed control.

Always

this Engineering is thought as a tool for the

fitter and

maintenance personnel, for that reason it is developed with the

necessary precision so that the officials of each specialty can

understand it.

The

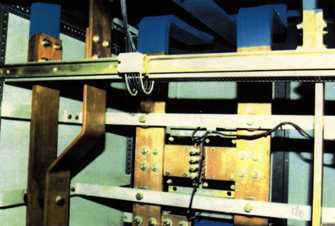

manufacture, works, services and special provisions, are

as diverse as: Installation of reliable energy systems for gas compressing

stations and complete refitting

in

compressing plants of all instrument

panels and control room, (TGS) and control rooms of

petroleum

refineries (SHELL, ISAURA, YPF) corrosion protection due to printed current

(Loma de la Lata Pipeline - TGS).

The

manufacture, works, services and special provisions, are

as diverse as: Installation of reliable energy systems for gas compressing

stations and complete refitting

in

compressing plants of all instrument

panels and control room, (TGS) and control rooms of

petroleum

refineries (SHELL, ISAURA, YPF) corrosion protection due to printed current

(Loma de la Lata Pipeline - TGS).

- Automatic Mixer Systems such as - Blending- of GASOLINE of Distillery La Plata YPF etc.

- Remodeling of the energy system in the Central Telefonica of Alta Cordoba.

- Remodeling of the Electrical systems and Instrumentation of the Coke, Crude and Drain furnaces of the Distillery at PF Lujan de Cuyo.

- Remodeling of the electrical components and instruments of the boiler heat recovery systems at Central Nuevo Puerto.

- Engineering and Assembly of Motive Power, Lighting Implementation, Security and ignition systems and Instrumentation of boilers 120 42 Th/h Kg/m in PGM.

- Remodeling of electrical Systems and Instruments in auxiliary boilers in Turbogroup Nº 7 Central Costanera.

- Engineering and Assembly of FM Systems, Illumination Command and implementation as well as plant control and security systems at MTBE Carboclor.

- Engineering and Assembly of Control and security Systems as well as FM and Command in Plant of Secondary Recovery at Yacimiento “El Tordillo”.

- Assembly and

furnishing in Plant Refinor Platforming of Average Voltage systems, F.M

implementation,

Illumination, Instrumentation and Security system in Campo Duran, Salta.

- Complete Instrumentation of Washing and Whitening plant at Celulosa Argentina Capitan Bermudez.

- Instrumentation

in 9000 Tons / day Soy Oil Plant of

in DREYFUS, General Lagos.

- Instrumentation, Complete

Control System installation, instruments of analysis, Motive Power, Average

Voltage Illumination, Implementation in gas separation Plant ASTRA FILO MORADO.

- Instrumentation,

Motive

Power Illumination, Average Voltage,

implementation

of Ethylbencene and Hydrogenation Plant in PASSES, Puerto San Martin.

We also are flexible in offering the provision of assembly materials, Instruments or only for the assembly, purchase and inspection of Instruments by the Client themself.

We work on the Projects with modern methods of programming so that we can carry out a follow-up task by task, as well as to verify automatically if the engineering standards and assembly are fulfilled correctly.

We maintain through our communications systems, permanent contact between engineering, purchases and administration in our central offices and headquarters with the supervisor of project to the aims of avoiding delays and to quickly correct any course of action that can alter the tasks that are in critical path.

Once assembly has ended, we provide with trained personnel to make all calibrations and tests as to leave the installations ready for launch. These tasks are made with pre-established procedures and the result are filled on calibration and control forms that allow monitoring loop by loop or equipment to equipment.

Our

tool stores are constituted by transportable modules whose

outer structure are metallic "Containers” that have been specially prepared as

DINING ROOM, LOCKERS, BATH, SUPERVISION OFFICE, WAREHOUSE, etc. with all the necessary elements for its

goals.

The personnel is equipped with individual manual tools, clothing and security elements corresponding to the conducted tasks including all related insurances.

Regarding

industrial safety, all measures are taken to give

our personnel all the elements of safety and training

them in their use, also maintaining the

obligation of their use, this exceeding actual regulations. Also short courses

on security and alcohol and drugs screening are carried out by the company to avoid its

consumption.

The Supervisors and foreman have instructions of being extremely rigorous in the application of security measures, nevertheless all the personnel is insured by first-rate Companies.

In each project the amount of vehicles is established to maintain suitable logistics. Before the start of any project and to carry out the “Scheduled Plan”, primarily it is considered the type and means of logistics regarding the region (accesses, lodgings, transports of materials and tools, etc.)

ADI SA

Bernardo De Irigoyen 1588 2nd Floor - Dto. 4 - C.P. 1138

CAPITAL FEDERAL - REPUBLICA ARGENTINA

TEL AND FAX: (5411) 4300-0907 ( rotary lines )

E-MAIL ventas@adi-sa.com.ar

* * * Copyright 1998 * * *

Web masters Horacio Alfano - alfatec@usa.net